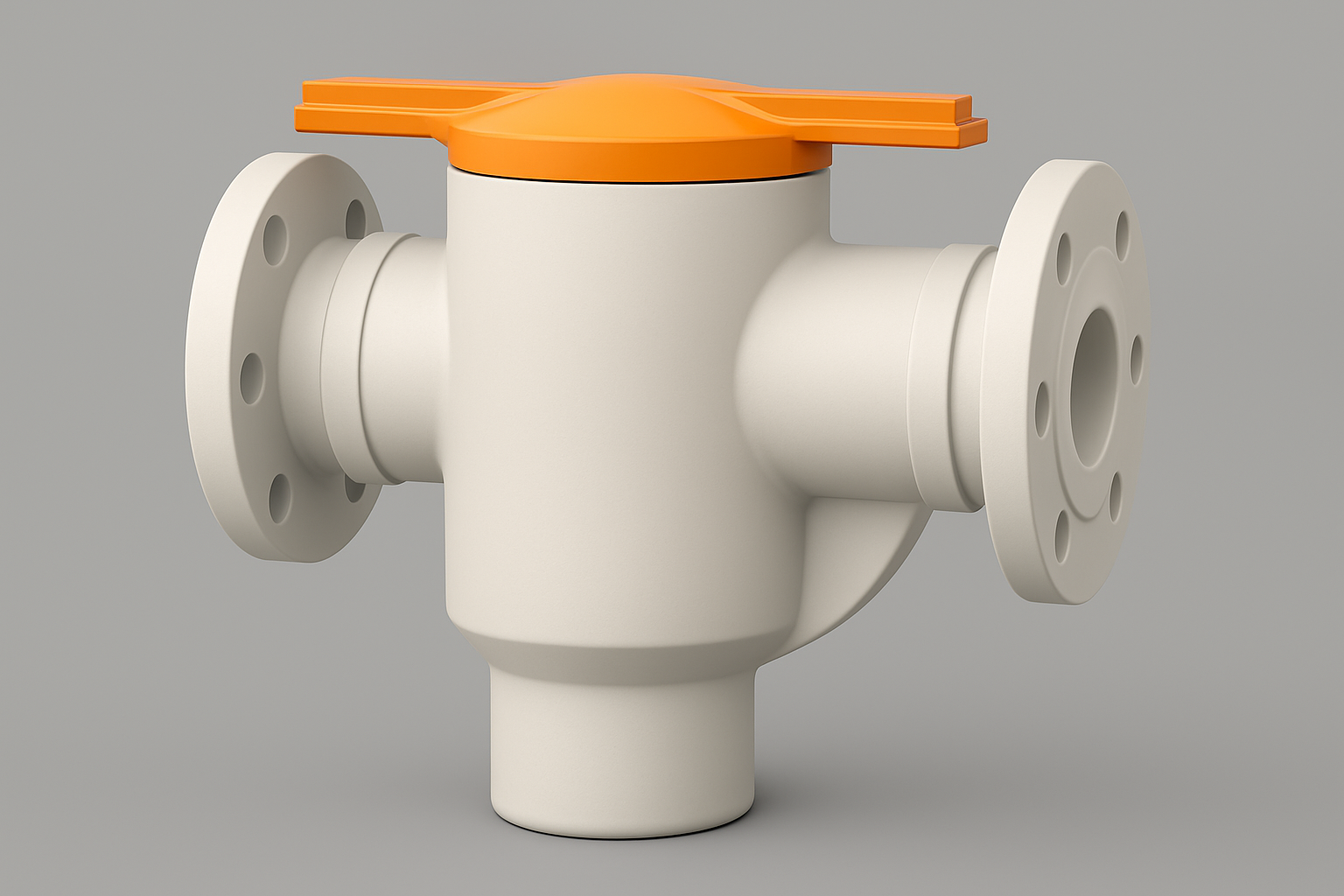

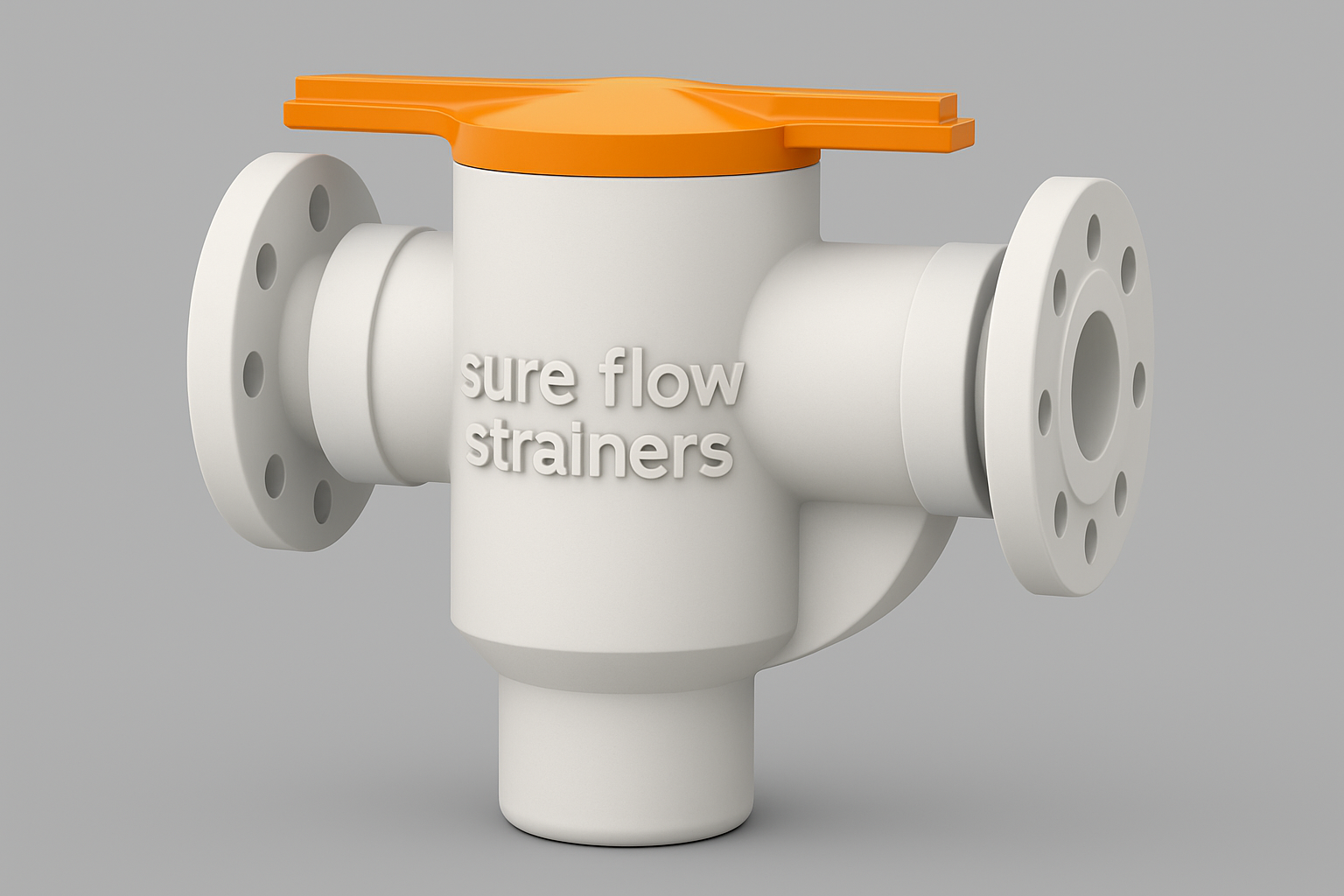

Basket StrainersHigh-Performance Protection

Essential filtration components designed to remove coarse particles, debris, and solid contaminants from liquid pipelines, protecting downstream equipment and maintaining system reliability.

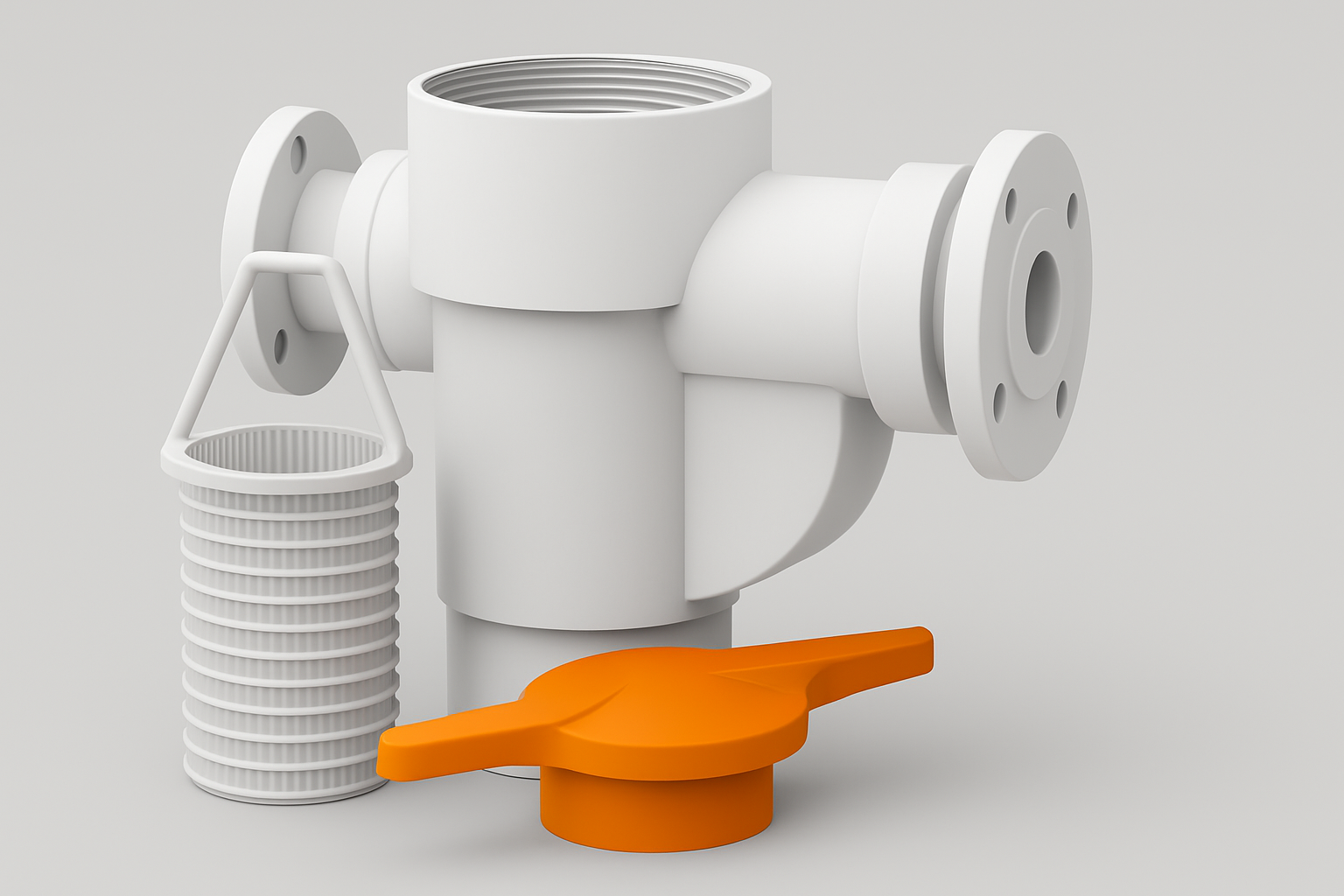

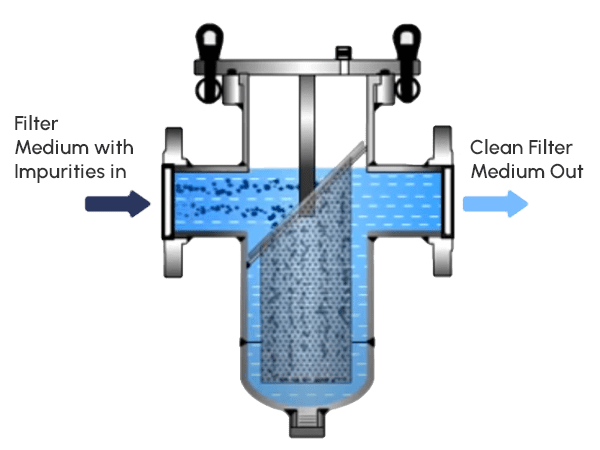

Filtration ProcessExplained

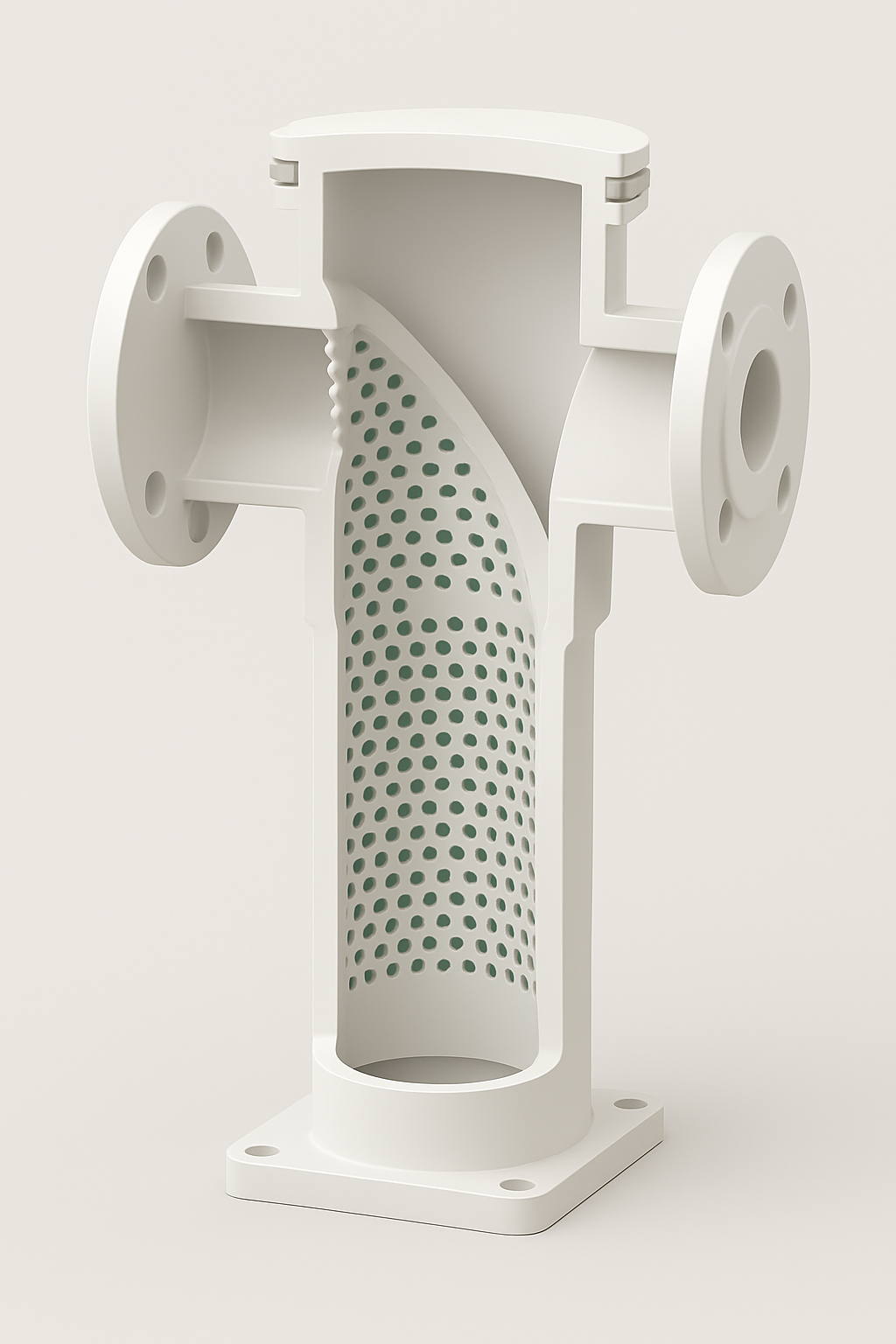

Basket strainers operate by channeling fluid through a housing that contains a perforated or mesh filter basket:

Contaminant Capture

As the liquid flows into the strainer, contaminants are trapped inside the basket.

Clean Flow Output

Clean, filtered fluid exits through the outlet and continues through the system.

Easy Maintenance

When the basket reaches capacity, it can be easily removed, cleaned, or replaced with minimal downtime.

Why ChooseBasket Strainers

Protects Critical Equipment

Prevents clogging and mechanical damage in pumps, valves, nozzles, heat exchangers, and instrumentation.

Low Maintenance & Easy Cleaning

Top-removal designs allow fast basket access, reducing process interruptions.

Durable Construction

Available in stainless steel, carbon steel, duplex steel, and other corrosion-resistant materials for enhanced longevity.

High Flow Capacity

Engineered for maximum throughput with minimal pressure drop, even in demanding industrial environments.

Customizable Filtration Levels

Choose from a wide range of mesh sizes and perforation options depending on process fluid and particle size.

Cost-Effective Solution

Extends equipment lifespan and reduces maintenance costs through effective debris removal.

CommonApplications

Widely used wherever particle filtration and equipment protection are essential.

Chemical Processing Plants

Removes solid impurities from process liquids to prevent contamination.

Petrochemical & Oil Refineries

Protects pumps and separators in high-pressure, high-temperature systems.

Water & Wastewater Treatment Facilities

Screens raw water and prevents debris from damaging treatment equipment.

Paints, Coatings, and Inks Manufacturing

Ensures product consistency and prevents nozzle blockage in production lines.

Food & Beverage Processing

Provides coarse filtration for liquids, syrups, oils, and CIP systems.

HVAC & Cooling Systems

Protects heat exchangers and cooling towers from debris buildup.

View OurBasket Strainers

Why Our Basket StrainersStand Out

Precision-engineered for industrial durability

Wide range of sizes, pressure ratings, and flange standards

Custom basket designs (mesh, perforated, duplex construction, etc.)

Optional features: differential pressure gauges, quick-open covers, magnetic traps

Designed for easy installation and long service life